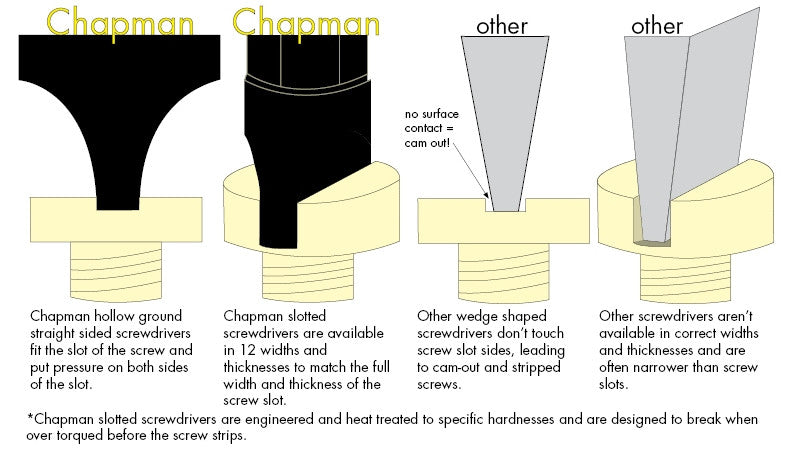

Slotted becomes far more tolerable when you have a hollow-ground screwdriver. Flathead screwdrivers should not have the profile of a wedge. They should look like this:

This profile ensures that the force is applied lower in the slot, not right at the very top edge.

I still HATE slotted screws when torque is required or where corrosion can occur, but the hatred of them is also partially due to shitty drivers.

Here’s a picture that says all of the above but far more concisely:

Even if the width of your driver doesn’t match, a hollow ground tool is still a huge improvement imo. I’m definitely not a fan of slotted screws though. I’d rather have Phillips head provided I have a super grippy Wera screwdriver.

For me, it’s outside hex > torx > pozidrive > internal hex > Phillips > JIS > slotted. I’ve never used a Robertsons screw so I can’t form an opinion on them.